Whether in prototype production, for small series, or customised components – with Hohnen you can rely on high precision, fast implementation, and maximum design freedom. We have been supporting our customers as a reliable partner in foundry and modelling requirements for over 100 years – now also in additive manufacturing.

Our service

CAD data creation: we can support you with the design of your components on request.

Production of components & moulds: manufactured on the basis of digital data – economical, dimensionally accurate, and reproducible.

Mechanical processing: Post-processing according to your specifications – for precisely fitting results of the highest quality.

Ready-to-use product: whether rapid prototyping casting or 3D printing – we supply components that can be used immediately.

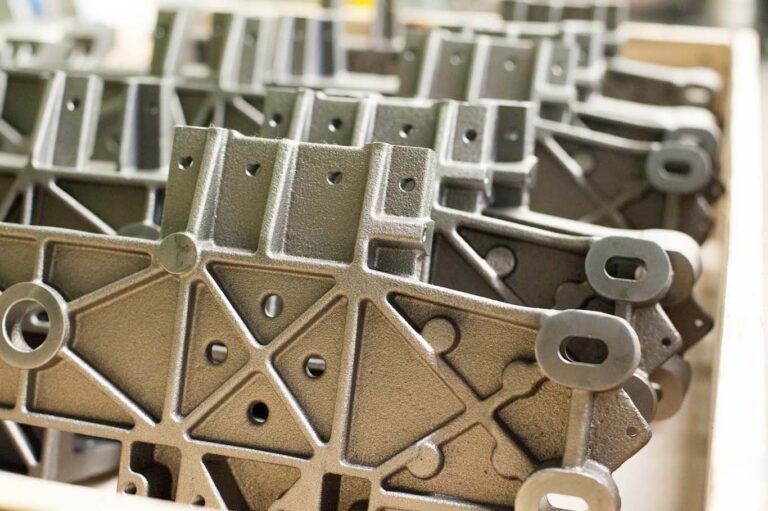

Metal 3D printing service – complex geometries, manufactured quickly

3D metal printing using the SLM (Selective Laser Melting) process produces components directly from CAD data – without the need for toolmaking or modelling. A high-precision laser melts fine metal powder layer by layer, allowing even complex structures and functional details to be produced with maximum dimensional accuracy.

Your advantages:

- Precise production with high surface quality

- Short production times thanks to direct realisation of digital data in SLM 3D printing

- High material efficiency through targeted powder application

- Ideal for functional prototypes, small series with high technical requirements, or spare parts without an existing model

Customised materials up to 50 kg are also possible – we will be happy to advise you.

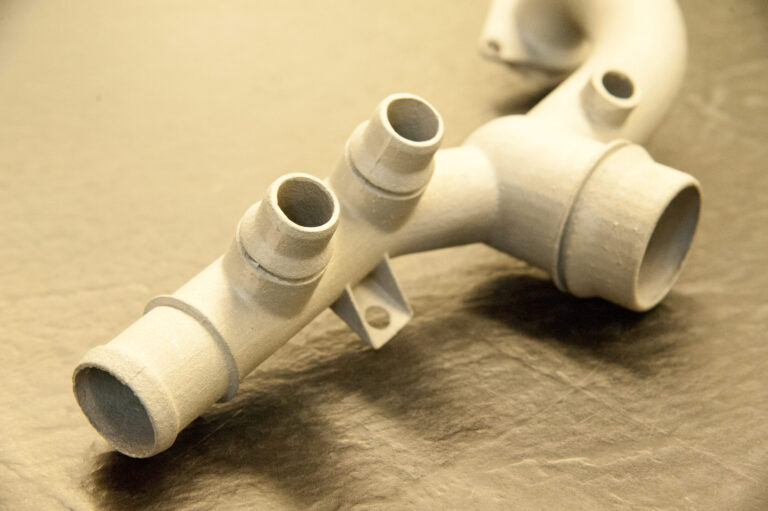

RP castings – functional & economical in prototype construction

With our RP cast parts made of aluminium, iron, steel, or magnesium, you can shorten development times and reduce the effort involved in model making. The rapid prototyping process makes it possible to create casting moulds directly from CAD data – without the need for traditional model production. Ideal for prototypes, test parts, and small series.

Your advantages:

- Reduced development time and costs – classic model production is not necessary

- Direct conversion of CAD data into moulds

- Ideal for functional prototypes, test parts, and small series

We also realise cast parts made from special materials weighing up to 50 kg – individually and reliably.

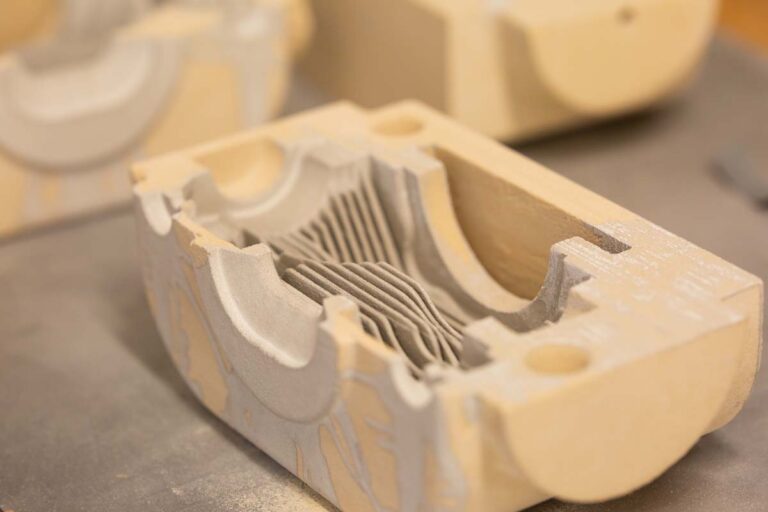

3D sand printing process - phenolic resin-bonded sand moulds & cores

With our innovative 3D sand printing process, we produce phenolic resin-bonded sand moulds and cores directly from digital design data – without the need for a physical model. This speeds up production, reduces preparation work, and enables even complex geometries to be produced in the shortest possible time.

Your advantages:

- Ideal for customised products, prototypes, and short production runs

- Precise contour results with minimal post-processing

- Improved surface quality saves time and costs

- No wooden model required as a template – this reduces the amount of material used and means lower logistics costs

- Sand and binder are applied in layers, excess sand is recycled

The 3D sand printing process is particularly suitable for prototype production, small series, functional components, and lightweight construction applications – wherever time, precision, and individuality are required.

Your partner for precise solutions – for over 100 years

Hohnen combines experience with innovation: Since 1918, we have stood for quality, personal advice, and economical solutions in foundry and modelling requirements – today also in additive manufacturing.

Let's start a conversation

Whether prototype production, 3D printing with metal, or 3D sand printing – we are at your side with expertise and experience. Benefit from our personalised advice and proven quality.